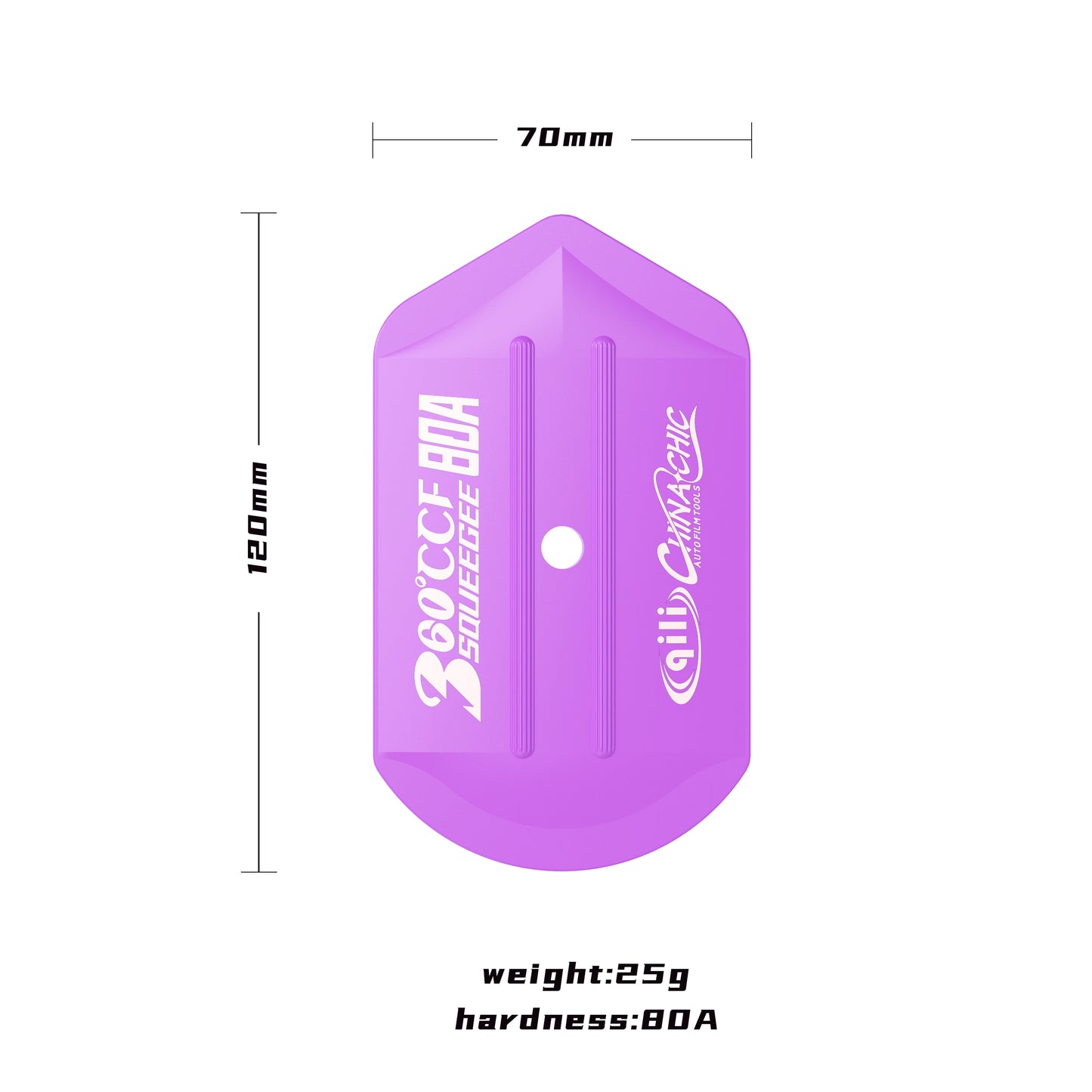

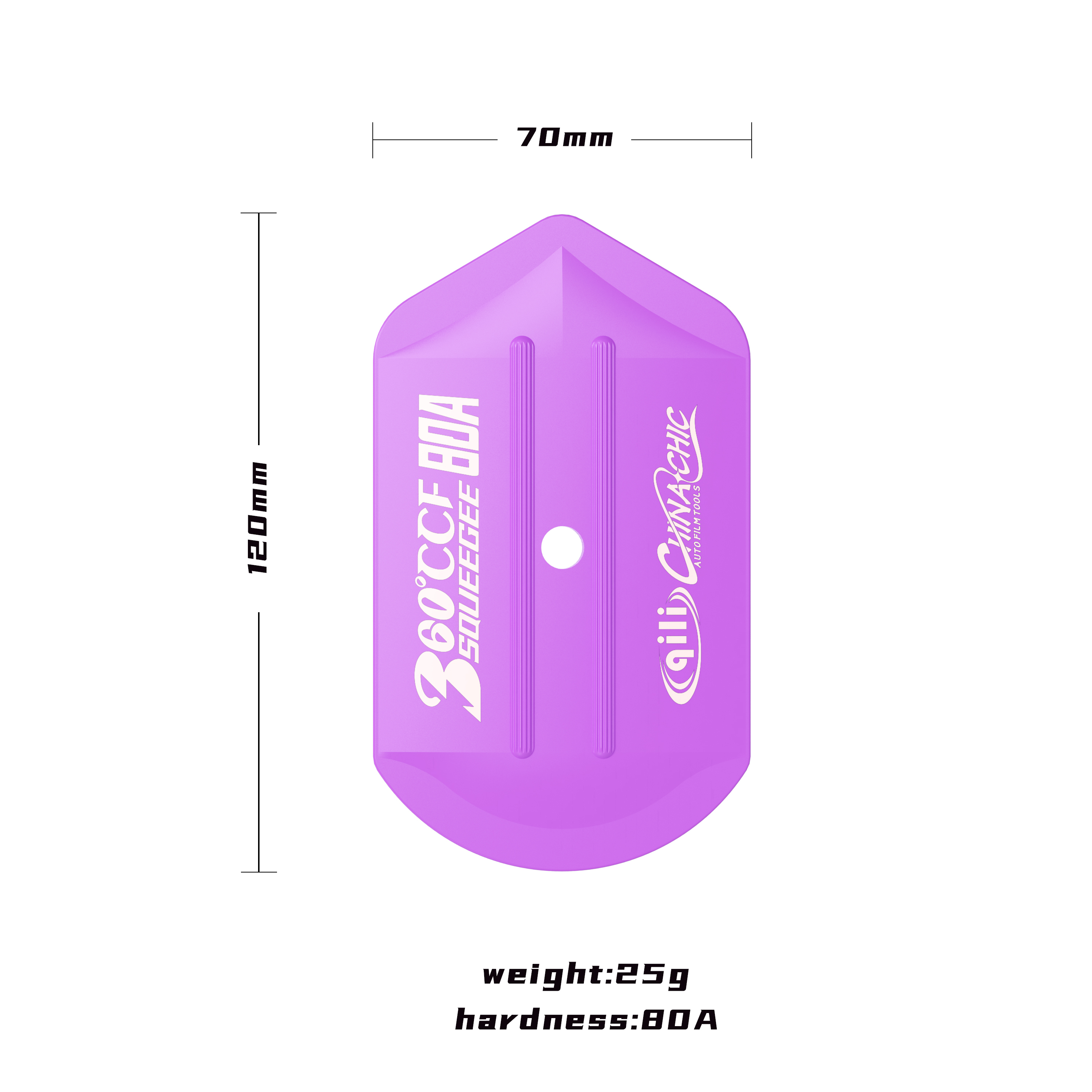

- Sold per piece, select from 80A or 60A hardness

- For wrapping purposes, the size is designed to be flexible in reaching out different types of edges

- For reaching small and tight areas

The hardness level of a squeegee is typically measured in durometer (Shore A), which determines its flexibility and stiffness. Here are the common hardness levels used in tint, PPF, and vinyl applications:

-

Soft (50-60 durometer)

- Best for curved surfaces and delicate films like window tint and PPF.

- Applies light pressure, reducing the risk of scratches.

-

Medium (70-80 durometer)

- Versatile for vinyl wraps, decals, and general film applications.

- Balances flexibility and firmness for smooth installations.

-

Hard (85-95 durometer)

- Ideal for removing water and air bubbles under thick films like PPF and heavy-duty vinyl.

- Applies strong pressure, making it effective but less flexible.